Workshop Capabilities

At Fabrication Specialists, it's not about having flashy gadgets—it's about having the right tools in the right hands. Our workshop in Silverdale, Auckland is fully equipped to take a project from raw steel through to site-ready installation, with accuracy and efficiency at every stage.

Watch our workshop in action, where design becomes steel.

Cutting & Shaping

Our guillotines and bench saws deliver clean, precise cuts that form the backbone of reliable fabrication. Whether it's sheet metal for featurework or steel sections for architectural work, accurate cutting ensures components fit perfectly from the start.

Used for: Feature steelwork, architectural steelwork, precision blanks

Forming & Bending

From folding sheet metal for flashings and cladding to forming steel for balustrades and architectural details, our forming equipment allows us to shape material to exact specifications. This ensures perfect alignment, tight tolerances and professional finish.

Used for: Balustrades, flashings, architectural panels, custom angles

Machining & Turning

Our lathe and machining capabilities let us refine components to precise dimensions, create custom fittings and produce one-off parts that can't be sourced off the shelf. This flexibility means we can deliver exactly what your project needs.

Used for: Custom fittings, threaded components, precision parts

Comprehensive Welding

Our MIG and TIG welding capabilities allow us to deliver everything from fine architectural detailing to robust fabrication work. Our team holds specialist welding certifications that ensure quality welds meet Australian and New Zealand standards.

Used for: Architectural features, balustrades, handrails, custom steel doors, stainless steel details, aluminium work

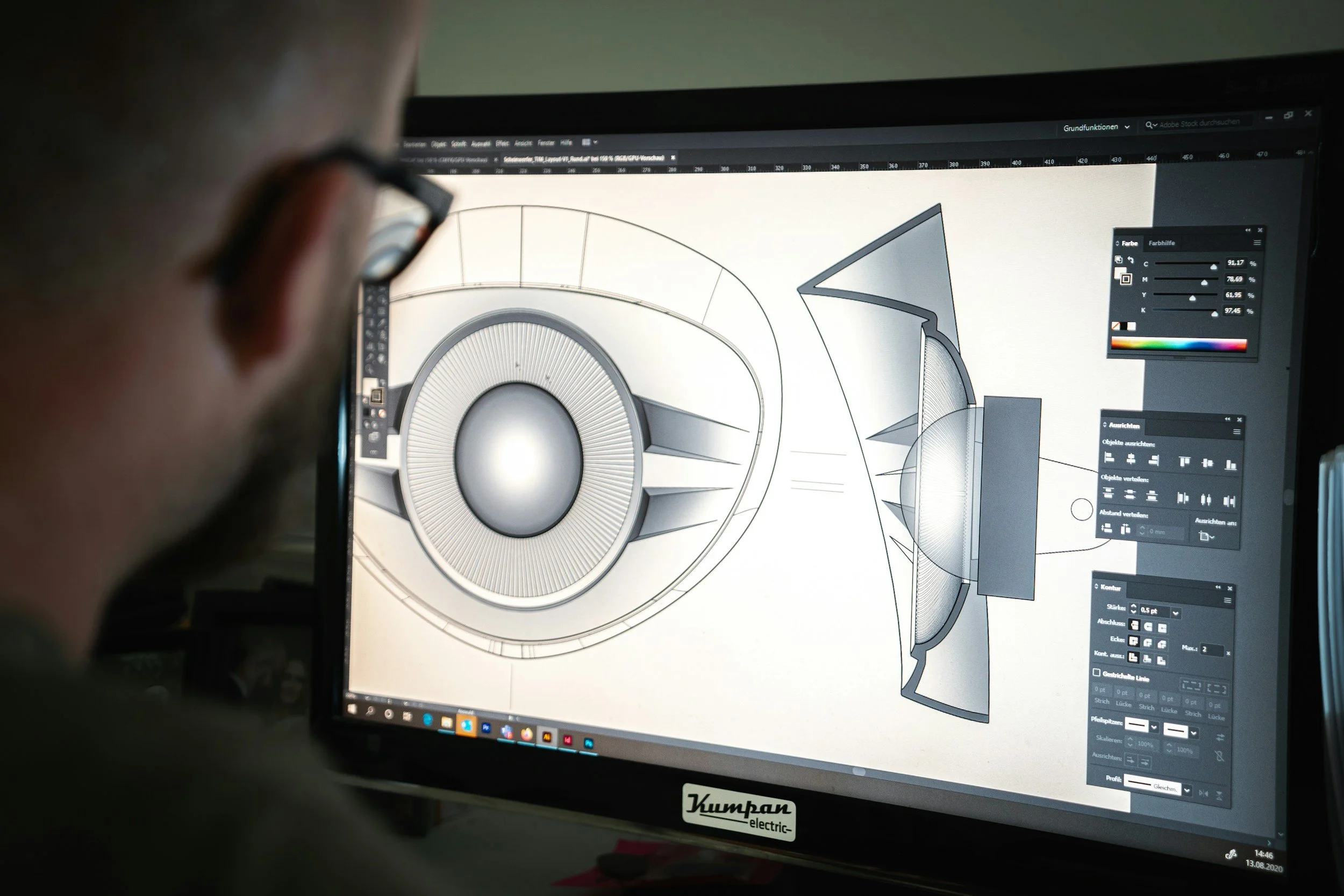

CAD Design & Modelling

Every project starts with design, with CAD modelling where needed. So what's designed is what gets delivered in steel. This digital precision saves time on site, eliminates costly surprises and ensures components integrate seamlessly with the rest of your build.

Used for: Design development, fabrication drawings, coordination with engineers and architects

Surface Finishing

From grinding and polishing to preparing steel for powder coating or galvanising, we handle surface preparation and finishing to spec. This attention to finish quality means your steelwork looks as good as it performs.

Used for: Architectural features, visible steelwork, corrosion protection preparation

Why In-House Capabilities Matter

✅ Complete control over quality at every stage

✅ Faster turnaround without relying on external suppliers

✅ Flexibility to adapt when site conditions change

✅ Direct communication between design and fabrication

✅ Cost efficiency through streamlined processes

✅ Accountability—one team, one point of contact

From Design to Delivery

By keeping these capabilities in-house, we maintain tight control over quality, adapt quickly when conditions change and give our clients peace of mind that their project is in skilled, reliable hands. Whether it's a small residential fabrication or a larger commercial contract, our workshop is equipped to deliver steelwork that's built to spec and designed to last.

Ready to See What Our Workshop Can Do?

Whether you have detailed drawings or just an idea, we'll work with you to understand what your project needs and deliver fabrication that meets your specifications. Get in touch to discuss your project and discover how our workshop capabilities can bring your vision to life.

Contact Dean on 021 183 1504 or dean@fabspec.co.nz to discuss your ideas.