From Prompt to Reality: Turning AI Steel Designs into Real-World Fabrication

Imagine sketching a bold steel staircase idea with AI, overlaying it on your living room and sending it to a fabricator. In this post, we explore how AI is changing the way homeowners, designers and architects visualise steelwork - and how we turn those digital dreams into tangible, buildable reality.

In this post:

1. The Rise of AI in Design & Visualisation

AI tools - such as generative image models, diffusion-based renderers, or prompt-to-image platforms - are rapidly entering the mainstream in architecture and interior design. Designers and homeowners alike are experimenting with prompts like “minimal steel spiral staircase in a light-filled room” and getting surprisingly vivid renderings. These early visualisations help clients, architects and fabricators align on aesthetic direction before detailed technical work begins.

In Auckland and across New Zealand, the architecture, engineering and construction (AEC) sector is already forming dedicated AI working groups to explore adoption and innovation in this space.

2. Why AI Helps — But Needs Human Skill

AI can fast-track ideation. It helps refine proportions, test finishes and visualise how steel elements sit in existing spaces (especially when overlaid on a client’s photograph). For homeowners, it gives more control and confidence in early design decisions. For architects and builders, it helps communicate ideas more clearly to clients or collaborators.

Yet AI outputs are not designs ready for fabrication. They often lack structural logic, connection detail, dimensional consistency and compliance with engineering standards. Many of today’s AI tools generate images purely based on learned visuals - without a built-in understanding of load paths, weld geometry, tolerances or fabrication constraints.

A recent review in steel structural engineering shows that AI and machine learning are being applied to predictive modelling, structural health monitoring, and inverse design (i.e. going from performance goals backward to geometry), but that bridging the gap to concrete structural design still requires expert oversight.

Similarly, in steel fabrication, AI is already being used to optimise production flows, quality control and custom part tweaking, but the “last mile” of design-to-fabrication still depends on human expertise.

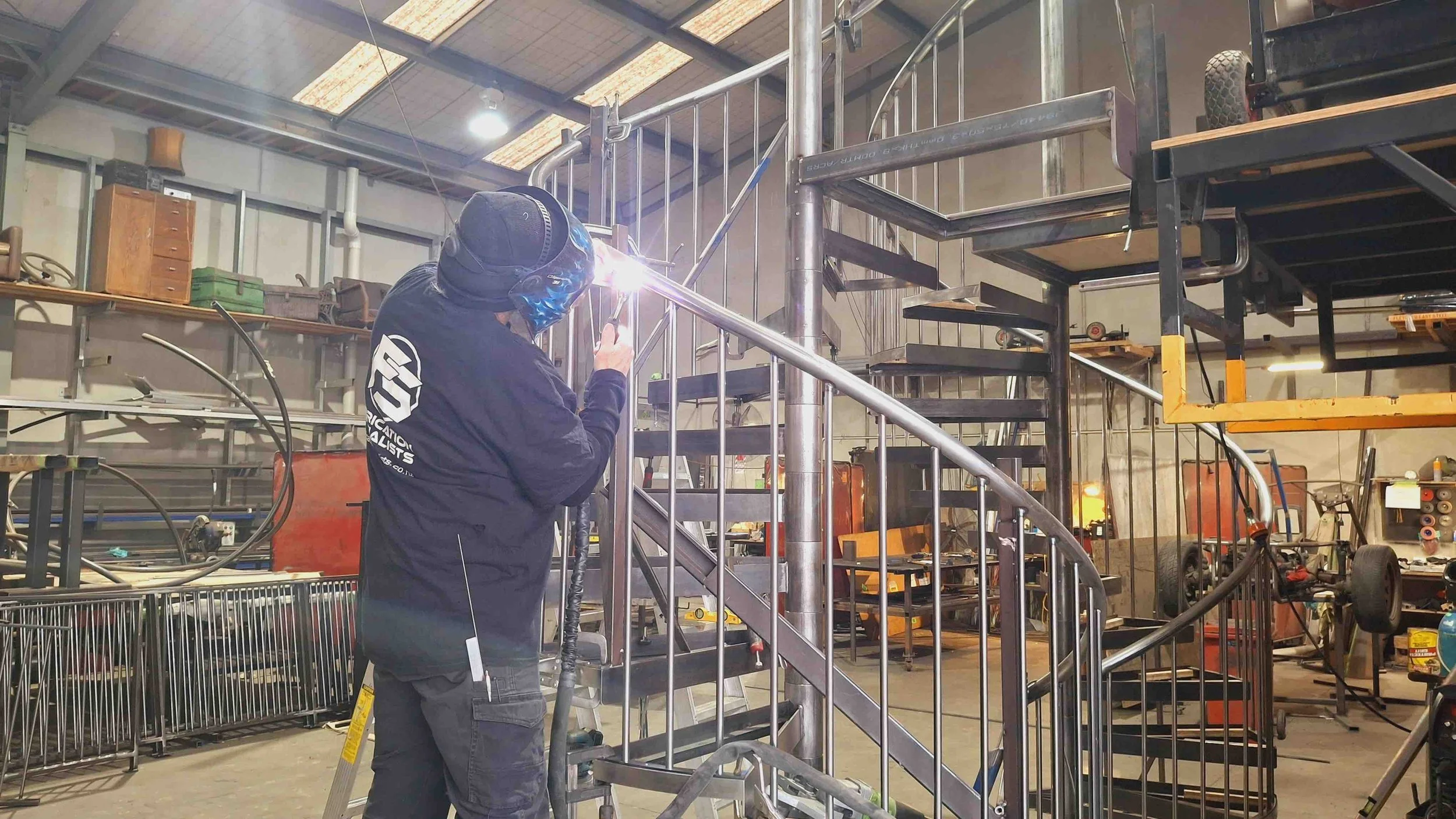

3. A Real Example: AI-Inspired Staircase, Fabricated for Real

Let’s walk through one of our recent projects:

A homeowner used an AI image generator (via prompt) to visualise a sleek, steel spiral staircase in their living area.

They overlaid that generated image onto a photograph of their room and sent it to us, saying, “This is roughly what I’m imagining.”

We used that as a visual reference, then translated the concept into precise structural checks, connection details and fabrication drawings.

We refined proportions, ensured compliance with NZ standards, selected appropriate steel grade/finish and crafted the staircase to exactly fit the space.

Because the AI image gave us a clear visual target, the iterative design discussions were faster and more focussed. The client, designer and fabricator had a shared visual language from day one.

This kind of workflow - with prompt, render, prototype, refine, build - is becoming an exciting interface between client imagination and fabrication reality.

4. Best Practices When Working from AI Designs

When a client or designer brings an AI-generated vision, here’s how we make it work smoothly:

Ask for multiple angles / views - Helps resolve ambiguous geometry and hidden structure.

Provide accurate room photos / measurement context - Ensures overlays are to scale and align with real space.

Treat AI as inspiration, not engineering - We must check structural integrity, material constraints and code compliance.

Be open to iteration - Some features may need slight adjustment for fabrication or installation.

Specify finish and durability early - AI might not account for corrosion, surface treatment or edge polishing.

Document changes clearly - Using 3D models and shop drawings ensures everyone is aligned before fabrication.

These steps help turn a dazzling AI render into a staircase (or balustrade, screen, or canopy) that is beautiful, safe and built to last. See more custom staircases we’ve built.

5. What This Means for Clients, Designers & Architects

Clients (homeowners): You can take charge of design early and bring your vision to life faster. AI visualisation offers more clarity, fewer surprises and more confidence in your decisions.

Designers & Architects: AI serves as a creative partner to explore forms and materials rapidly. When handed to a capable fabricator, you shorten feedback loops and reduce misinterpretation.

Fabricators: Embracing AI-driven workflows allows us to work more responsively and creatively. It’s not about replacing skill - it’s about amplifying collaboration.

At Fabrication Specialists, we’re excited by this convergence of creativity and technology. We encourage clients and collaborators to bring AI-inspired ideas, and we bring the steel-making knowledge to bring them into reality.

6. End-of-Year Inspiration: Looking Ahead

As 2025 draws closer, we look to a future where every beautiful idea, whether from your mind or an AI prompt, can be realised with precision, elegance and structural intelligence. The path from concept to steel is evolving - and we’re here to walk it with you, combining imagination, fabrication and craftsmanship.

Have an AI-generated steel concept you’d like to see built?

Send us your prompt imagery or renderings and let’s talk about how to turn it into craftsmanship you can touch and live with. Contact Fabrication Specialists today for a design consultation and quote.